Fruitron Ripening Systems

PLC Based Automatic Ripening Systems

Fruitron 2.0

Dedicated automatic PLC based ripening controller for 1 room.

Automated solution by Chemtron, best suited for ripeners targeting premium quality ripened fruits with precision control datalogging.

This solution is best suited for ripening chambers of 12 to 40 tons of fruit capacity.

The controller controls temperature, RH, Ethylene and CO

2 based on sensor feedback which ensures repetitive and most efficient ripening process.

Features:

- One dedicated controller with colour touch interface with trends, graphs and USB data logging

- Two independent indoor fan control, 2 compressor control

- Three pre-set fruit ripening recipe and 1 manual recipe

- Four defined process precool, dosing, venting and post cool

- Defrost and compressor protection logic

- Energy saving by smart control logics

- Audio visual alarms

- Auto fall back to time based operations if sensor fails

- SCADA monitoring possible

Specifications:

- Enclosure: SS316

- Mount: Wall

- Input: 230 VAC, 50 Hz.

- Control output: 230 VAC

- Number of control output: 8 per room

| Parameter |

Monitor |

Control |

| Temperature |

Ambient Temperature with range 0 to 50 degC.

Pulp Temperature (upto 4 probes) which can be inserted into the fruit. |

Controls up to 2 indoor units and 2 outdoor units.

Can operate solenoids for Ammonia based refrigeration. |

| Relative Humidity |

Ambient RH between 10 to 98 % |

Operates humidifiers which are controlled by sensor feedback and hysteresis logic. |

| Ethylene |

Measures Ethylene in the range

0 – 200 ppm. |

Operates Gas Dispensing Unitsthat releases desired Ethylene into the ripening chambers. |

| Carbon Dioxide |

Measures CO2 in the range 0 – 3.2%. |

Operates CO2 and fresh air dampersto remove the excess CO2 build up in the chamber. |

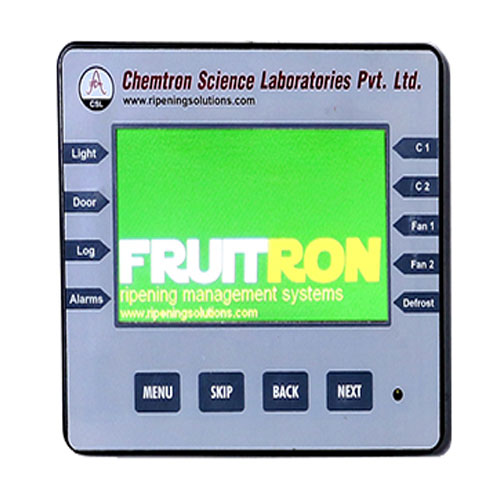

Four Room PLC Ripening System

Fruitron 3.04FA

Automatic PLC based ripening controller for 4 room.

Automated solution by Chemtron, best suited for ripeners targeting premium quality ripened fruits with precision control datalogging.

This solution is best suited for ripening chambers of 12 to 40 tons of fruit capacity.

The controller controls temperature, RH, Ethylene and CO

2 based on sensor feedback which ensures repetitive and most efficient ripening process.

Features:

- Dedicated controller with alphanumeric display

- Weather proof enclosure for outdoor installation

- One control output to control refrigeration contactor

- Four defined process precool, dosing, venting and post cool

- Visual alarm

- Auto fall back to time based operations if sensor fails

- SCADA monitoring possible

Specifications:

- Enclosure: SS316

- Mount: Wall / Floor

- Input: 230 VAC, 50 Hz.

- Control output: 230 VAC

- Number of control output: 4 per room

| Parameter |

Monitor |

Control |

| Temperature |

Ambient Temperature with range 0 to 50degC. |

One control output to control refrigeration contactor.

Can operate solenoids for Ammonia based refrigeration. |

| Relative Humidity |

Ambient RH between 10 to 98 % |

Operates humidifiers which are controlled by sensor feedback and hysteresis logic. |

| Ethylene |

Measures Ethylene in the range

0 – 200 ppm. |

OperatesGas Dispensing Unitsthat releases desired Ethylene into the ripening chambers. |

| Carbon Dioxide |

Measures CO2 in the range

0 – 3.2%. |

Operates CO2 and fresh air dampersto remove the excess CO2 build up in the chamber. |

10 Room PLC Ripening System

Fruitron Centralized Management Systems

Central panel supports up to 10 rooms.

Automated solution by Chemtron, best suited for ripeners targeting premium quality ripened fruits with precision control datalogging.

This solution is best suited for ripening chambers of 12 to 40 tons of fruit capacity.

Completely automated that controls parameters based on sensor feedback which ensures repetitive and most efficient ripening process.

Monitor parameters such as Temperature, RH, CO

2 and Ethylene.

Control Temperature, RH, CO

2 and Ethylene.

Sampling based Ethylene detection.

PLC, HMI and SCADA based system.

Data log on customer’s computer.

Potential free relay output to control Temperature and RH.

Features:

- Centralized panel with colour touch interface of 7” with trends, graphs and USB data logging

- Simultaneous Independent control of all rooms

- Four defined process precool, dosing, venting and post cool

- Troubleshooting and diagnostics mode present

- Energy saving by smart control logics

- Audio visual alarms.

- Auto fall back to time based operations if sensor fails

- SCADA monitoring

Specifications:

- Enclosure: MS IP56 Powdercoated panel

- Mount: Floor

- Input: 230 VAC, 50 Hz.

- Control output: 230 VAC

- Number of control output: 4 per room

| Parameter |

Monitor |

Control |

| Temperature |

Ambient Temperature with range 0 to 50 deg C.

Pulp Temperature (upto 4 probes) which can be inserted into the fruit.

|

Controls up to 2 indoor units and 2 outdoor units.

Can operate solenoids for Ammonia based refrigeration. |

| Relative Humidity |

Ambient RH between 10 to 98 % |

Operates humidifiers which are controlled by sensor feedback and hysteresis logic. |

| Ethylene |

Measures Ethylene in the range

0 – 200 ppm.

Detection is based on sampling where air samples are sucked from the ripening room andanalyzedinside the panel. |

OperatesGas Dispensing Unitsthat releases desired Ethylene into the ripening chambers. |

| Carbon Dioxide |

Measures CO2 in the range

0 – 3.2%. |

Operates CO2 and fresh air dampersto remove the excess CO2 build up in the chamber. |

Auto Ripening Systems

Model: Fruitron 1.01FA

Dedicated ripening controller that supports one ripening room.

Advanced automated solution from Chemtron best suited for medium to large scale ripeners targeting premium quality of ripened fruits.

This solution is best suited for ripening chambers of 8 to 24 tons of fruit capacity.

The controller controls temperature, RH, Ethylene (*to be bought separate) and CO

2 based on sensor feedback which ensures repetitive and most efficient ripening process.

5 preset recipes for different commodities.

The controller is connected to our sensor module for monitoring of Temperature, RH and CO

2.

| Parameter |

Monitor |

Control |

| Temperature |

Ambient Temperature with range 0 to 50 deg C.

Pulp Temperature which can be inserted into the fruit. |

One relay output for refrigeration control. |

| Relative Humidity |

Ambient RH between 10 to 98 % |

One relay outputto operate humidifiers which are controlled by sensor feedback and hysteresis logic. |

| Ethylene |

Measures Ethylene in the range

0 – 200 ppm (optional) |

One relay output to operateGas Dispensing Unitsthat releases desired Ethylene into the ripening chambers. |

| Carbon Dioxide |

Measures CO2 in the range

0 – 3.2%. |

One relay output to operate CO2 and fresh air dampersto remove the excess CO2 build up in the chamber. |

Ethylene Control: (without Ethylene sensor)

User can set dose time between 10 – 99 hours in 10 intervals as required by the commodity and market conditions.

The controller controls Ethylene gas in the room by dispensing it in short bursts at fixed intervals of time.

User can set frequency of dosing between 1 to 99 cycles of desired time period between 5 to 20 seconds.

The controller ensures 100 to 150 PPM of Ethylene during the dosing time irrespective of the losses of Ethylene due to leakages in the cold room.

Works best with our Gas Dispensing Unit (GDU).

Features:

- One dedicated controller for each room

- One relay output for the control of Temperature, RH, Ethylene and CO2

- Fout pre-set fruit ripening recipe and 1 manual recipe

- Four defined process precool, dosing, venting and post cool

- Auto fall back to time based operations if sensor fails

- GPRS based messaging possible (To be bought separate)

Specifications:

- Enclosure: SS316

- Mount: Wall

- Input: 230 VAC, 50 Hz.

- Control output: 230 VAC

- Number of control output: 4

4 Room Semi-Automatic Ripening Systems

Model: Fruitron 1.04SA

Centralized ripening controller that supports 4 ripening rooms.

Cost effective automated solution from Chemtron best suited for small scale ripeners targeting average to good quality of ripened fruits.

This solution is best suited for ripening chambers of 6 to 12 tons of fruit capacity.

The controller controls ethylene dosing and CO

2 venting based on preset time intervals by the user.

Ethylene Control:

- User can set dose time between 10 – 99 hours in 4 intervals as required by the commodity and market conditions

- The controller controls Ethylene gas in the room by dispensing it in short bursts at fixed intervals of time

- User can set frequency of dosing between 1 to 99 cycles of desired time period between 5 to 20 seconds

- The controller ensures 100 to 150 PPM of Ethylene during the dosing time irrespective of the losses of Ethylene due to leakages in the cold room

- Works best with our Gas Dispensing Unit (GDU)

CO2 Control:

- User can program CO2 vent time between 24 to 125 hours and venting frequency as per required stage of ripening for the targeted market

- The controller controls venting of CO2 in the room by controlling dampers / blowers at regular intervals of time that is user settable up to 30 minutes for every 5 hours

- The controller ensures air exchange happens in the ripening room in order to keep CO2 generation in check

- Works best with our CO2 Dampers

Specifications:

- Enclosure: SS316

- Mount: Wall

- Input: 230 VAC, 50 Hz.

- Control output: 230 VAC

- Number of control output: 2 per room

| Fruitron 1.04 SA |

Dose Process |

Vent Process |

| Settings |

Time: 10 to 99 hours

Intervals: 4

Frequency: 1 to 99 cycles

On Time: 5 to 20 seconds

Off Time: 20 - 45 seconds |

Time: 24 to 125 hours

On time: 5 to 30 minutes

Off Time: 15 – 300 minutes |

| Control Output |

230 VAC |

230 VAC |

| Control Device / Accessory |

Gas Dispensing Unit (GDU) |

CO2 Dampers |

8 Room Semi-Automatic Ripening Systems

Model: Fruitron CRC8 3.0SA

Centralized ripening controller that supports 8 ripening rooms.

Cost effective automated solution from Chemtron best suited for small scale ripeners targeting average to good quality of ripened fruits.

This solution is best suited for ripening chambers of 6 to 12 tons of fruit capacity.

The controller controls ethylene dosing and CO

2 venting based on preset time intervals by the user.

Ethylene Control:

- User can set dose time between 10 – 99 hours in 4 intervals as required by the commodity and market conditions

- The controller controls Ethylene gas in the room by dispensing it in short bursts at fixed intervals of time

- User can set frequency of dosing between 1 to 99 cycles of desired time period between 5 to 20 seconds

- The controller ensures 100 to 150 PPM of Ethylene during the dosing time irrespective of the losses of Ethylene due to leakages in the cold room

- Works best with our Gas Dispensing Unit (GDU)

CO2 Control:

- User can program CO2 vent time between 24 to 125 hours and venting frequency as per required stage of ripening for the targeted market

- The controller controls venting of CO2 in the room by controlling dampers / blowers at regular intervals of time that is user settable up to 30 minutes for every 5 hours

- The controller ensures air exchange happens in the ripening room in order to keep CO2 generation in check

- Works best with our CO2 Dampers

Specifications:

- Enclosure: SS316

- Mount: Wall

- Input: 230 VAC, 50 Hz.

- Control output: 230 VAC

- Number of control output: 2 per room

| Fruitron CRC8 3.0SA |

Dose Process |

Vent Process |

| Settings |

Time: 10 to 99 hours

Intervals: 4

Frequency: 1 to 99 cycles

On Time: 5 to 20 seconds

Off Time: 20 - 45 seconds |

Time: 24 to 125 hours

On time: 5 to 30 minutes

Off Time: 15 – 300 minutes |

| Control Output |

230 VAC |

230 VAC |

| Control Device / Accessory |

Gas Dispensing Unit (GDU) |

CO2 Dampers |

Ripening Accessories

Gas Dispensing Unit (GDU)

Gas dispensing unit distributes Ethylene inside the ripening chamber as directed by the ripening controller.

Features:

- One GDU supports upto 5 ripening chambers (except for mango pulping chambers where one GDU supports one room)

- Comes with all-weather stainless-steel housing with diffusion resistant constant flow apparatus with precision control

- GDU supports both traditional 47 litre cylinder fittings as well as Ripylene 200 cartridges

- The dispensing unit has pressure gauges for inlet and outlet pressure, comes with a Chemtron proprietary instant fit adaptors which connect to any C10 valve

- Regulator comes with precision seals like kalrez and has safety release valve for over pressure scenarios

- Weather proof connectors for electrical connection

- Flow indicator indicates the gas that is going inside the ripening chamber

- IP-68 weather proof connectors for gas release mechanism

Gas Exhaust Damper for CO2 venting

For ventilation of ripening chambers chemtron manufactures state of the art dampers. These dampers accomplish air exchange and removes the CO2 build up inside the chamber which is detrimental to ripening process.

Specifications:

- Enclosure: SS316

- Mount: Wall

- Input: 230 VAC, 50 Hz.

- Control output: 230 VAC

- Number of control output: 2 per room

| Ripening Chamber capacity |

Damper solution |

Number of blowers |

Number of safety relief valve |

CFM |

| 2 to 8 tons |

Single blower damper with safety relief valve |

1 |

1 |

100 |

| 8 to 12 tons |

2 blowers for air inlet and CO2 exhaust |

2 |

No |

100 |

| 12 to 20 tons |

2 blowers for air inlet and CO2 exhaust |

2 |

No |

150 |

| 20 to 30 tons |

4 blowers for air inlet and CO2 exhaust |

4 |

No |

150 |

| 30 tons and above |

Customized Solutions |