Post Harvest Technologies

Controlled Atomosphere Systems

To store fruits for some duration you need refrigeration and to extend this duration by 2 to 3 folds you need a controlled atmosphere (CA) storage solution. In CA, fruit specific Oxygen (O

2), Carbon dioxide (CO

2) and Ethylene (C

2H

4) is maintained along with temperature for the very maximum storage duration.

After years of research and development we have launched completely indigenised Controlled Atmosphere (CA) storage solutions for the long term storage of fruits and vegetables. We provide the latest technology which has now become a benchmark for these systems for Indian conditions. The solutions are cost effective that will cost you approximately 1600 to 1900 Rs. / Ton for facilities of 5000MT to 2500 MT.

The CA system consists of the following components :

- Nitrogen generator

- CO2 scrubber

- CA gas analyser

- CA room accessories

Features :

- Indigenously built for Indian conditions

- A single compact skid with the complete CA solution that can support up to 12 chambers

- An all-encompassing composite panel for gas analyzing, Nitrogen purging and Carbon dioxide scrubbing

- Accurate analysis of chamber atmosphere that leads to precise release of Nitrogen and control of Carbon dioxide to keep the room within desired ranges

- Temperature and RH monitoring, control and data logging for flawless environment control

- Auto calibration and verification, auto trouble shooting and manual over ride possible

- All critical spares available locally

Specifications :

| Model |

CA Capacityin MT |

Maximum number of chambers |

N2 Generator flow in m3 /hr |

|

CO2 Scrubber |

|

Air Compressor Flow in m3 / hr @ 10 to 13 Kg / cm2 |

Gas Analyzer |

Skid Size

l x w x h (meters) |

Connected load in kW |

| Output @ 5% O2 |

Output @ 1% O2 |

Scrubbing capacity in Kg of CO2 per day |

Scrubbing vessels |

| CSL-CAS-100 NCG |

100 |

12 |

5 |

1 |

75 |

1 |

20 |

Room O2, CO2, Ethylene and Ammonia (optional) |

2.7 x 2 x 2 |

5 |

| CSL-CAS-500 NCG |

500 |

12 |

7.5 |

1.5 |

75 |

1 |

30 |

|

2.7 x 2 x 2 |

6 |

| CSL-CAS-1000 NCG |

1000 |

12 |

10 |

2 |

125 |

1 |

50 |

|

2 x 2.7 x 2 |

8 |

| CSL-CAS-2500 NCG |

2500 |

12 |

40 |

5 |

250 |

2 |

160 |

|

4 x 2.7 x 2 |

35 |

| CSL-CAS-5000 NCG |

5000 |

12 |

80 |

16 |

500 |

2 |

300 |

|

5 x 2.7 x 2 |

70 |

Palletized CA

With Palletized CA you can :

- Extend the shelf life of a fresh produce by 2 or 3 folds just like in a CA store

- Convert any normal cold room into a CA store

- Minimize losses

- Be flexible with the harvest output

- Sell as per market requirements to maximize profit

What is Palletized Controlled Atmosphere (CA)?

Palletized CA is a compact CA where the commodities are stored in specialized pallets with a simple transparent bag to cover the pallet to make it air tight. Think of this as a bigger version of modified atmosphere packaging of a bag of chips or vegetables, where the sealed air composition of the bag is prefixed that gives an extended shelf life to the packed commodity. Once sealed, these pallets are kept in cold store under controlled atmosphere conditions until the product is ready to market.

Why go for Palletized CA?

Flexible

The storage system proves to be flexible where the user can store commodity as per availability and harvest. User can also sell the commodity stock as per market conditions and requirement without disrupting CA in other pallets.

Control

Control is faster in Palletized CA as free air volume is negligible inside the pallet bags. The controlling of gas composition is quick, precise and conditions are met immediately.

Diverse

Product-specific atmosphere can be achieved in individual pallets hence this system is perfectly suitable for wide range of fruits and vegetables to be stored under CA conditions in the same cold room.

Cost Effective

Palletized CA does not require CO

2 & Ethylene scrubbers, air tight rooms and specialized CA doors. The cost of operation will depend on the number of pallets the user uses for storage. This makes palletized CA cheaper both in terms of capital investment and running cost.

Modular

Single or multiple pallets can easily be removed or added to the system without affecting the conditions of the other pallets.

Robust

With Palletized CA commodities can be stored into pallets immediately after harvest within 1 to 2 hours. As soon as the precooling is achieved Oxygen pulldown in next 5 hours and

2 can be introduced directly from high purity cylinders.

What does Palletized CA comprise of?

- Gas analyser control panel

One panel can control up to 100 pallets. Analyser will analyse CO2, O2 and Ethylene at regular intervals and control the gas concentration as required depending on the commodity

- Nitrogen Generator

Palletized CA requires smaller Nitrogen generators. Our generators are based on Polyamide membrane that can reach purity of 99.5% N2 with no moving parts, requires no consumables and have and high performance and long life

- Specialized Pallets

These are specialized pallets which have specialized fittings to make the system air tight. Commodities have to be stored in crates or in corrugated boxes. Maximum load capacity of pallet is 1.5 Tons. The commodities can be stored vertically up to 12 feet high

- Airtight Pallet Bags

The pallet bags are used to cover the commodity placed on the pallet, they are durable and transparent that is made of Polyurethane film. This helps user to visually inspect the commodity during the storage phase. The bags are reusable

- Accessories

Push fit airtight connections for gas interfaces to the bags, PU tubes for gas flows, manifold for CO2 cylinders, food grade CO2 Cylinders

Palletized CA is very cost effective and suitable for various size growers and traders. Different type of fruit and vegetables can be stored in a product-specific atmosphere in a common room and will help to supply the highest quality and the correct quantity on market demand.

Modified Atmosphere

According to the FDA, modified atmosphere packaging "involves either actively or passively controlling or modifying the atmosphere surrounding the product within a package made of various types and/or combinations of films." There are two different kinds of modified atmosphere packaging, Passive and active. We have solutions for active Modified Atmosphere Packing (MAP) where the gases in the package are displaced and replaced by a desired mixture of gases. Our solution includes MAP analyzers, MAP gas mixtures and scrubbers for modified atmosphere cold storages.

MAP Analyzers:

We have online analyzers for cold rooms and also benchtop analyzers for sampling from modified atmosphere packaging bags.

Features:

Our cold room analyser can monitor CO

2 and Ethylene levels in every cold room through room sampling principle and control the CO

2 and Ethylene scrubbers. The centralized panel can monitor up to 10 rooms. If required the same panel can monitor other cold room parameters such as room ambient temperature and RH. All parameters can be monitored, controlled and data logged through our SCADA on the customers PC.

Our Benchtop analyser can sample gas from a MAP bag with the help of a needle and a miniature vacuum pump with low flow rates much as 60 ml/min. The analyzer can analyze CO

2, O

2 and Ethylene in as low as 30 seconds. The analysed parameters can be datalogged with timestamp and batch number for quality assurance. For more details please go to Bench Top Gas Analyzers.

MAP Gas mixtures:

For packing of commodities in Modified Atmosphere Packaging bags we can provide premix gas cylinders with compositions specified by you. The cylinders that are used for the MAP gases mixtures are conditioned and sterilized to remove all the impurities and VOC to maintain food grade gas standards. The cylinder is also tracked to make sure no industrial mixture or gases are filled in it to maintain premium quality of the mixture.

Various compositions premix gas mixtures are as follows:

| Sr. No. |

Gas type |

Gas mixture |

Cylinder |

Purity |

| 1 |

Mono Gas |

100 % CO2 |

10 litre, 47 litre and 50litre |

Food grade |

| 2 |

100 % N2 |

| 3 |

Dual Gas |

10% CO2, balance N2 |

| 4 |

5% CO2, balance N2 |

| 5 |

3% CO2, balance N2 |

| 6 |

2% CO2, balance N2 |

| 7 |

1 % CO2, balance N2 |

| 8 |

Triple Gas |

10% CO2, 5% O2, balance N2 |

| 9 |

5% CO2, 5% O2, balance N2 |

| 10 |

3% CO2, 3% O2, balance N2 |

| 11 |

2% CO2, 2% O2, balance N2 |

| 12 |

1 % CO2, 1% O2, balance N2 |

We can provide you custom mixture for research and studies.

MAP Scrubber:

For converting your existing cold storage in to Modified Atmosphere cold storages we offer CO

2 scrubbers and Ethylene scrubbers.

CO2 Scrubbers:

Some commodities have higher respiration rate and hence higher amount of CO

2 is generated. When these commodities are stored in bulk in cold storages they build up higher concentration of CO

2 will lead to anaerobic respiration, degrading fruits texture firmness and colour. To avoid degrading quality of stored commodity we manufacture CO

2 scrubbers and this product is primarily used for Potato, Apple and Carrot cold storages. The advantages of CO

2 scrubber in the cold room are:

- Maintains CO2 between 2000 to 3000 PPM

- No refrigeration loss during CO2 scrubbing

- Cheap consumable that needs to be changed every 5 years

- Unit is placed outside the chambers hence cold room volume is not compromised

- Auto detection and control of CO2

- Data logging and centralized monitoring on customer's computer

Ethylene Scrubbers:

For storing commodities which are very sensitive to Ethylene we have Ethylene scrubber which filters out the Ethylene generated by the commodity. The scrubber will help maintain Ethylene within 5 ppm in the room. The scrubbers are based on Ethylene absorber granules and needs to be changed after 3 to 5 months of using the scrubber.

Advantages:

- Ethylene absorber removes the ethylene to extend the storage life of the products stored

- Ethylene absorber cleans without harming the fruits and environment

- Better quality of commodity maintained during storage

- Ethylene absorber removes the bad smell

Models:

| Model |

Fruit Capcityin MT |

Cold storage Volume in m3 |

Adsorbergranule capacity in Kg |

Connected Load in kW |

| CSL ES 100 |

0 - 100 |

Up to 750 |

12.5 |

1 |

| CSL ES 200 |

101 - 200 |

Up to 1500 |

25 |

2 |

Memberane Based N2 Generator

We are the manufacturers of membrane based nitrogen generators that gives constant flow of high quality nitrogen at a low operating cost. The Nitrogen generators have various applications across many industries such as:

- Controlled Atmosphere cold storages

- Tyre filling

- Autoclaves and Furnaces

- Blanketing applications for many industries (agro, pharmaceuticals)

- Fire prevention (server rooms)

- Laboratories

Features:

- Nitrogen production using Membrane technology which assures long life with minimal maintenance

- Best in the world membranes imported from Japan, Netherlands and the USA

- No Mechanical moving parts

- Instant Nitrogen generation, generation on demand

- Noise free Nitrogen production

- Nitrogen generated is oil free, dust free and VOC free that’s helps to keep the commodity clean

- Variable Nitrogen output from 90% to 99.5%

- Models from 5 m3/hr to 60 m3/hr as required as per free air volume

- Smart controls enables quicker pulldown, can be fully automated for unattended operation

- Saves time cost and energy

- Safe as it works at low pressures and there is no hazardous waste generated

- Cheaper than PSA, lower installation costs, low operating and maintenance cost

Specifications:

| Model |

Operating pressure in Kg/Cm2 |

N2 outout in m3/hr |

| @ 5 % O2 |

@ 1 % O2 |

@ 0.5 % O2 |

| Model CSL-N2G-10M3A |

10-13 |

10 |

2 |

1 |

| Model CSL-N2G-20M3A |

10-13 |

20 |

5 |

2 |

| Model CSL-N2G-40M3A |

10-13 |

40 |

15 |

5 |

| Model CSL-N2G-60M3A |

10-13 |

60 |

20 |

10 |

CO2 Scrubbers

When a commodity respires it consumes O

2 and produces CO

2. If the concentration of carbon dioxide gets too high, the quality of the fruit deteriorates. A CO

2 scrubber can prevent by removing the carbon dioxide from your storage rooms and ensures that the fruit retains its optimum quality.

A CO

2 scrubber removes CO

2 from gastight cold stores for fruit and vegetable storage. The amount of carbon dioxide that must be scrubbed depends on factors like type of product, the dimensions of the storage area and the conditions under which the commodity is being stored. Once the scrubbing requirement for the connected storage cells is known, the desired level of carbon dioxide can be maintained using the CO

2 scrubber. Activated carbon CO

2 scrubbers are a more energy-efficient method for CO

2 control than molecular sieve absorber (MSA) units.

In an activated carbon scrubber, the activated carbon bed is loaded into the scrubber vessel. The room air with CO

2 is made to pass through the activated carbon bed. Activated carbon adsorbs has selective adsorption that binds CO

2 and allows purified air to be reintroduced into the air. The scrubber has 2 activity cycle.

- Scrub cycle / adsorption cycle: removal of the carbon dioxide

- Purge cycle / regeneration cycle: cleaning or regenerating the active carbon filter.

- Premium grade made in India activated carbon ensures long life without physical disintegration

- CO2 scrubbing capacity from 50 Kg CO2 per day to 1000 Kg CO2 per day on a single skid

- Controlled using SS316 pneumatic valves which are sturdy with 10,000 cycle operational life

- Scrub and purge cycle control switching based on sensor feedback enabling stringent CO2 control in the chamber

- Maintains CO2 between 2000 to 3000 PPM

- No refrigeration loss during CO2 scrubbing

- Cheap consumable that needs to be changed every 5 years

- Unit is placed outside the chambers hence cold room volume is not compromised

- Auto detection and control of CO2

- Data logging and centralized monitoring on customer’s computer

Specifications:

| Model |

Room loading capacity in MT |

Activated Carbon in Kgs |

No. of Vessels |

Connected Load in kW |

| CSL-CAS-100NCG |

100 |

250 |

1 |

2.5 |

| CSL-CAS-250NCG |

250 |

500 |

2 |

5 |

| CSL -AS-500NCG |

500 |

1000 |

1 |

5.5 |

| CSL-CAS-1000NCG |

1000 |

2000 |

2 |

12 |

CA Accessories

Sensor Module

Temperature is a crucial parameter for controlled atmosphere systems, so it us very important to monitor, control and data log temperature. Our sensor module enables user to record ambient as well as 4 other temperature from four zones inside the cold room.

Features:

- Smart Sensor Module with RS 485 communication protocol

- Ambient and pulp temperature probes

- RH sensor with temperature compensation

- Choice of adding upto 8 more sensors

- IP 65 suited for coldroom applications

Breather Bags

Breather bags / buffer bags / lungs acts as air buffer to safeguard CA chambers from negative pressure which can induce air leakages in the cold room. Breather bag stores CA air which is required during CO2 scrubbing and helps in maintaining optimum level of O2.

Features:

- Made from 100 um industrial PVC

- UV stabilized for maximum life

- Material pressure tested till 40 mm WC

- Fused seal for 100% leak tightness

- Available in 2 to 10 m3 size

- Light weight

- Easy to install and service

Safety Valves

Safety relief vales keep the CA chamber safe from high and low pressure which are developed during CA operations. Our relief valves are based on simple weight based principles guaranteeing lifelong service free operation.

Features:

- Compact pressure relief valve for positive and negative pressure

- Adjustable positive pressure from + 1mmWC to 10 mmWC

- Adjustable negative pressure for room leak testing

- Rubber seals with Flange joint to eliminate leaks

Manometers

Alcohol based manometers to monitor chamber pressure during room testing and controlled atmosphere applications.

Features:

- Acrylic body

- Alcohol based

- Range – 15 to 15 WC

Post Harvest Research Chamber

Sustainable solutions for research organizations in the field of post-harvest technologies such as institutes, KVKS, UASs and local agricultural bodies.

It can be used for:

- Conducting research on ripening

- Conducting research on Controlled Atmosphere Storage

- To study the effect of waxing and other chemicals & gases

- To validate shelf life of fruit and vegetable

- To standardize and monitor the output quality of their fruits

Features:

- It comes with ports to introduce gases inside the chamber

- Glass doors for visual inspection of commodity from outside

- Adjustable trays as per users convenience

- Controls Temperature and RH

- Ultrasonic mist for humidity control

- Data logging onto USB and SCADA on customers PC

- Trends and graphs on HMI

- User programmable set points for each parameter

- Customizable as per client’s request

Sensing and Control Parameters:

| Sr. No. |

Sensor |

Range |

Status |

Quantity |

| 1 |

Ethylene |

10 - 50000 PPB or 0.01 - 50.0 PPM |

Online |

1 |

| 2 |

CO2 |

0.0 - 5.0 % |

Online |

1 |

| 3 |

Oxygen |

0.0 - 25.0% |

Online |

1 |

| 4 |

Temperature |

0.0 - 50.0 ⁰C |

Online |

1 |

| 5 |

RH |

0 - 100 % |

Online |

1 |

| 6 |

Temperature PULP |

0.0 - 50.0 ⁰C |

Portable |

1 |

| 7 |

Ethylene |

0 - 500 PPM |

Portable |

1 |

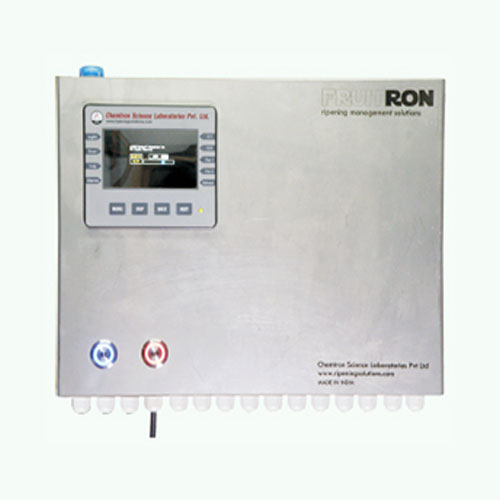

Potato / Mushroom Controller

An automatic controller which precisely monitors and controls Temperature, RH and CO

2 for optimal growth of mushroom indoors.

The control panel features are as follows:

- Monitor and control Temperature, RH and CO2

- Temperature, RH, CO2 sensors are placed inside each room

- Temperature monitoring of compost / substrate (up to 4 zones in each room)

- 4 potential free relay output per room

- 4.3" Colour Touch HMI

- PLC control

- Data logging onto USB and SCADA on customer’s PC

- Trends and graphs available on HMI

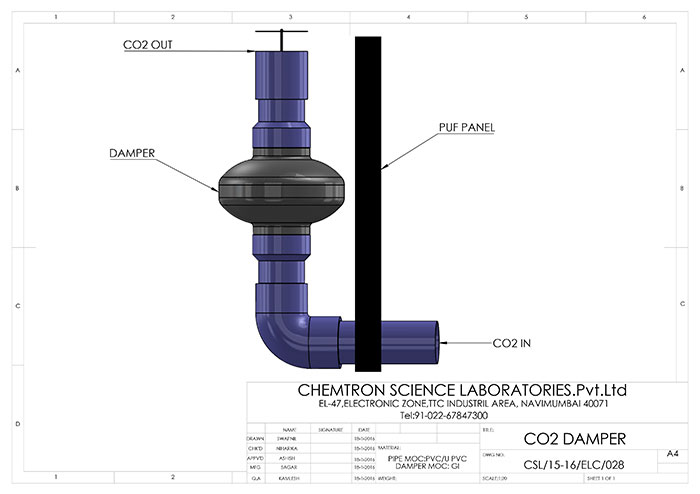

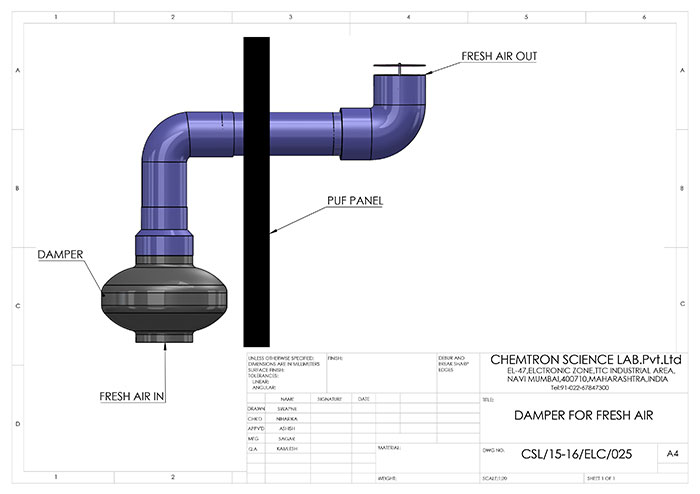

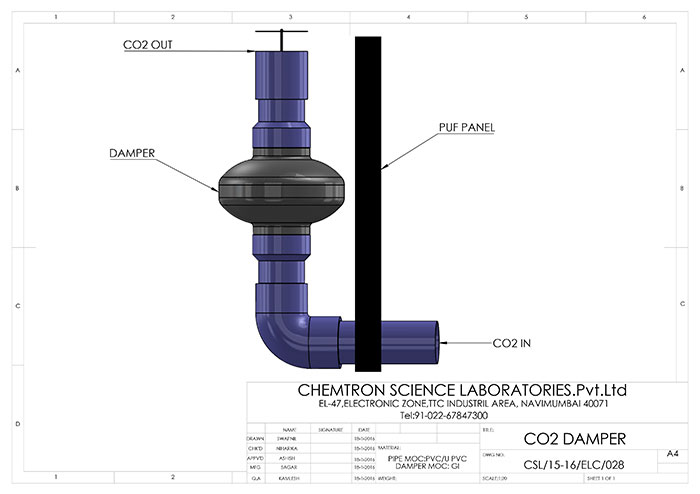

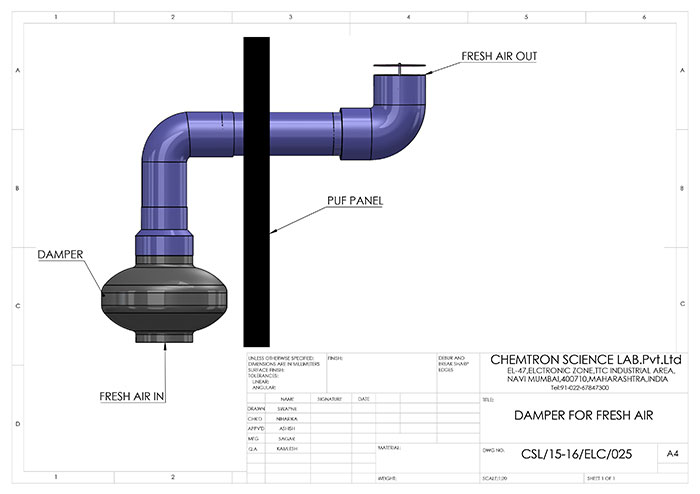

CO2 exhaust system:

- Specialized dampers are needed in Mushroom chambers to exhaust CO2

Features:

- Available in 100 and 150 CFM

- It removes the CO2 build up but does not allow light to enter the room

- Circular PVC connections and fittings hence no leakages in the room

- Weight based operations, no actuators or mechanical moving part

- No recurring cost, easy to maintain